Existing problems in the use of traction wire rope

Existing problems in the use of elevator traction steel wire ropes

In recent years, various elevator accidents have not only caused huge losses to people's lives and property, but also brought panic to people. As an important physical device, traction steel rope is a key equipment for the normal operation of the elevator. Maintenance inspection is a necessary measure to ensure the daily safe and stable operation of the elevator. In order to improve the safety and stability of the traction steel rope, standardized management measures should be adopted in the detection and inspection of the traction steel rope, and modern monitoring and supervision technology should be adopted.

Elevator traction steel wire rope is an important traction tool and an important tool for the safe movement of the elevator. It also faces various pressures during the work. Therefore, there will be some dangerous situations. the following:

In the first case, the diameter is getting smaller and smaller under the effect of continuous breaking force. The main reason for this phenomenon is that during the use process, due to the large load of the elevator, the extreme tension of the wire rope is exceeded, the yield strength is achieved, and the deformation cannot be recovered, resulting in the sudden thinning of the traction steel rope; This is also an important reason for the thin wire rope. Its carrying capacity is significantly reduced, damaging the reliability and safety of the elevator operation.

The second case is the corrosion of the wire rope. When using the elevator, the wire rope is exposed to the air for a long time. The moisture will oxidize the surface of the wire rope, severely damage the tensile strength of the wire rope, resulting in an increase in the force of the unit area, which will affect the overall performance of the wire rope and significantly shorten the use time of the wire rope.

In the third case, the wire was broken inside the wire rope. The traction steel wire rope is coincided with multiple steel wires. The more the number of steel wires, the decrease in the force of each steel wire, so the number of steel wire ropes will have a significant impact on the strength of the wire. In the process of repairing the wire rope, be sure to pay attention to the internal wire of the wire rope to avoid further damage to the steel wire rope.

In the fourth case, the wire rope was tightened. In the first three weeks of the elevator, each group of steel ropes will be arranged again to adapt to the weight of stacking, so there will be unstable exercise during this time. After a period of use, the flexibility of the wire rope is stable, and the elevator runs normally. At this time, the length of the wire rope is also limited.

Elevator traction steel wire rope is an important traction tool and an important tool for the safe movement of the elevator. It also faces various pressures during the work. Therefore, there will be some dangerous situations. the following:

In the first case, the diameter is getting smaller and smaller under the effect of continuous breaking force. The main reason for this phenomenon is that during the use process, due to the large load of the elevator, the extreme tension of the wire rope is exceeded, the yield strength is achieved, and the deformation cannot be recovered, resulting in the sudden thinning of the traction steel rope; This is also an important reason for the thin wire rope. Its carrying capacity is significantly reduced, damaging the reliability and safety of the elevator operation.

The second case is the corrosion of the wire rope. When using the elevator, the wire rope is exposed to the air for a long time. The moisture will oxidize the surface of the wire rope, severely damage the tensile strength of the wire rope, resulting in an increase in the force of the unit area, which will affect the overall performance of the wire rope and significantly shorten the use time of the wire rope.

In the third case, the wire was broken inside the wire rope. The traction steel wire rope is coincided with multiple steel wires. The more the number of steel wires, the decrease in the force of each steel wire, so the number of steel wire ropes will have a significant impact on the strength of the wire. In the process of repairing the wire rope, be sure to pay attention to the internal wire of the wire rope to avoid further damage to the steel wire rope.

In the fourth case, the wire rope was tightened. In the first three weeks of the elevator, each group of steel ropes will be arranged again to adapt to the weight of stacking, so there will be unstable exercise during this time. After a period of use, the flexibility of the wire rope is stable, and the elevator runs normally. At this time, the length of the wire rope is also limited.

Aulone is a major international provider of elevator ropes. The high-performance ropes are manufactured for a variety of applications and stand out due to their long service life. Aulone provides comprehensive service to its customers worldwide. Elevator systems, for example, can be quickly assembled with special ropes and rope end terminations ready for installation.

The basic of Elevator Ropes

Ropes for Elevators - There are two basic ways for an elevator to move up and down. Hydraulic jacks reign supreme in low-rise applications (buildings with two to four floors). Depending on the circumstances and need, the jacks can be in-ground or above-ground, single stage or telescopic, and can provide nearly 100 feet of travel. They are usually the best option if you only want to go up a couple of floors.When you reach five floors or more, you must consider several options, and once your elevator requirements exceed 100 feet, there is really only one way to go: a roped system. The only exception is a hybrid that employs both ropes and hydraulics (roped hydraulic).

With that said, let's take a quick look at elevator ropes and the various types found in elevators. To begin, when we say ropes in elevators, we don't mean the ropes you climbed in gym class or made a lasso out of when playing Cowboys and Indians.

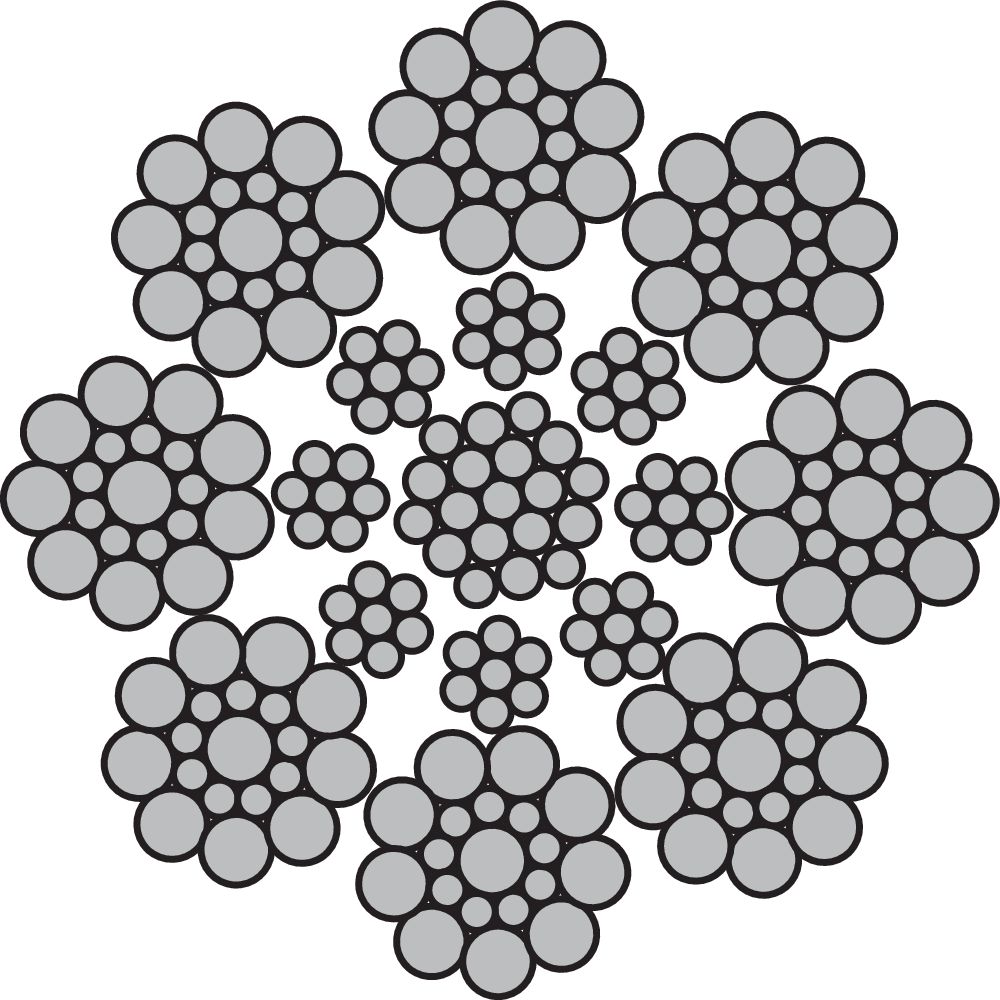

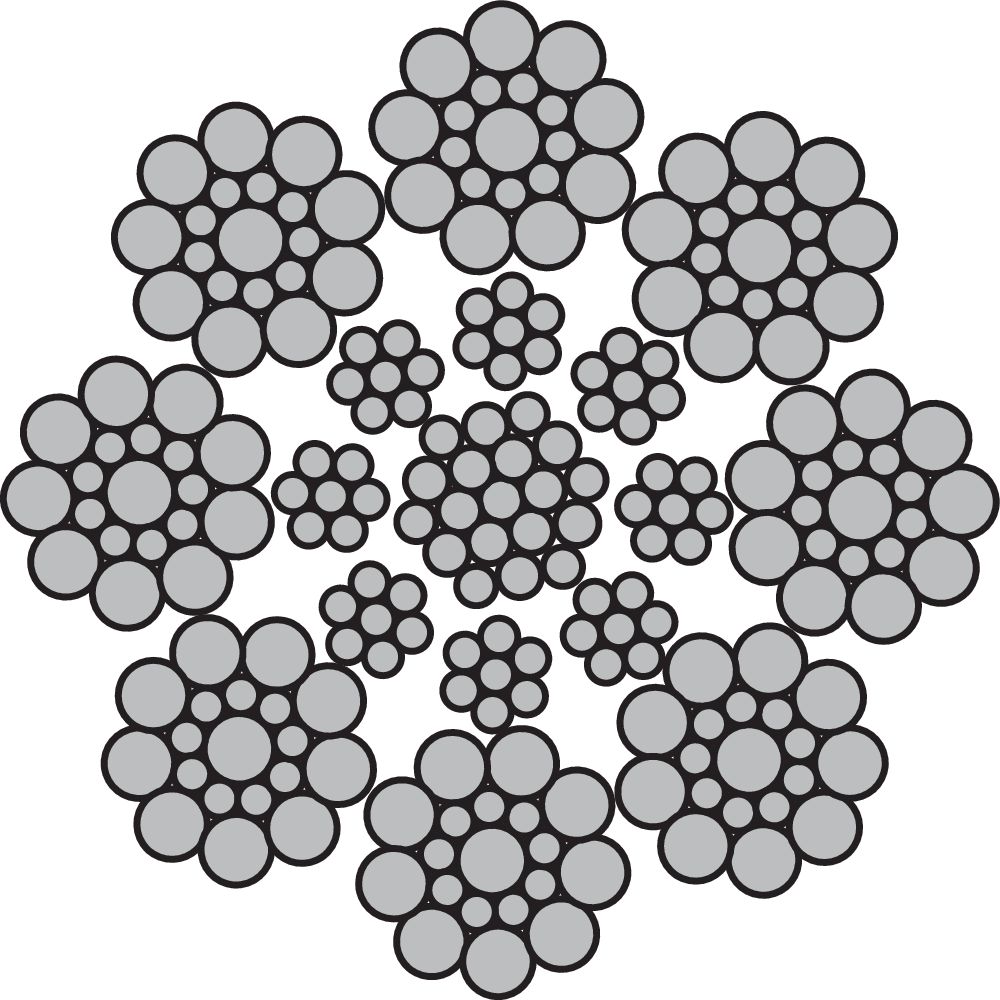

Elevator ropes are highly engineered composites made of steel. They are also not single wires, but rather many strands of varying widths coiled together. A typical cable or rope may contain over 150 strands of wire that have been precisely constructed to be strong, flexible, and long-lasting. Multiple wire strands are utilized to extend the cable's life and provide flexibility. When a cable is passed through a pulley wheel or sheave, the part of the wire on the sheave travels faster than the outside of the wire. A single strand would become weak as a result of this stretching over time. Elevator ropes are hence flexible, strong, and long-lasting if properly maintained.

The types of rope used in elevators can vary depending on the job at hand. Here are a some of the more frequent ropes you might see in your hoistway:

Hoisting Ropes

These are the ropes that you see in movies. A number of them are employed to suspend the elevator cab and move the car up and down. Because the counterweights and elevator vehicle are in the same system, these are also the cables utilized for both. The counterweights accomplish exactly what their name implies: they balance the weight of the elevator car when it is loaded, making it easier to move the vehicle up and down. Because of the required speeds, high-strength ropes are employed in high structures nowadays.For example, the world's fastest moving elevator car reaches speeds comparable to those found on freeways: 45 miles per hour! Finally, the steel quality is controlled not only by the speed but also by the automobile capacity. The more the weight that the car can lift, the greater the strength required.

Governor Ropes

A governor is an elevator safety feature that can be found in the hoistway or overhead space. When an elevator car begins to fall or rise too quickly, the governor activates the safety mounted on the car frame and brings the car to a halt. The governor rope is attached to the safety trip mechanism and runs over the governor sheave and down to the elevator car. The governor rope continues all the way down to the pit, where it runs under a sheave before returning to the governor.While the elevator moves up and down the hoistway, the governor rope arrangement forms a continuous loop. If the car accelerates too quickly, centrifugal force pushes flyweights in the governor outward against the spring. In layman's terms, it tells the brakes to engage and prevents the car from falling or rising too quickly. Because the governor rope is the foundation of this entire safety system, it must be reliable and in good working order.

Compensating Ropes

It turns out that the cable or rope used to move an elevator car up and down is quite heavy. This is especially true for extremely tall structures. Consider this: a standard one-inch elevator cable can weigh up to 1.85 pounds per foot. This weight can quickly add up as the elevator cable makes several trips up and down the hoistway. As a result, compensating ropes "compensate" for the entire weight of hoisting ropes on the car or counterweight side. These ropes, which are connected to the sling that holds the car and the counterweight frame, are probably required in any elevator that travels more than 100 feet.

The most important aspect of any elevator rope is that it be in good working order at all times. This means inspecting frequently. When performing routine checks, the technician must inspect the ropes closely for proper tension, any wear patterns, the diameter of the rope, any rusting, pitting, or breaks in the strands, the sheaves, proper lubrication, and connections.

So, when you choose a traction elevator, you will pay significantly more in monthly maintenance fees. You will also need to monitor the frequency of visits and the length of time the mechanic spends in the machine room, overhead, and hoistway. You're paying through the nose, so make sure they're doing what they're supposed to be doing. If you have any questions, talk to an elevator consultant, work with the elevator inspector, ask lots of questions, and discuss your concerns. If all else fails, contact another independent elevator technician to inspect the situation and provide an opinion on current maintenance.

Governor Ropes

A governor is an elevator safety feature that can be found in the hoistway or overhead space. When an elevator car begins to fall or rise too quickly, the governor activates the safety mounted on the car frame and brings the car to a halt. The governor rope is attached to the safety trip mechanism and runs over the governor sheave and down to the elevator car. The governor rope continues all the way down to the pit, where it runs under a sheave before returning to the governor.While the elevator moves up and down the hoistway, the governor rope arrangement forms a continuous loop. If the car accelerates too quickly, centrifugal force pushes flyweights in the governor outward against the spring. In layman's terms, it tells the brakes to engage and prevents the car from falling or rising too quickly. Because the governor rope is the foundation of this entire safety system, it must be reliable and in good working order.

Compensating Ropes

It turns out that the cable or rope used to move an elevator car up and down is quite heavy. This is especially true for extremely tall structures. Consider this: a standard one-inch elevator cable can weigh up to 1.85 pounds per foot. This weight can quickly add up as the elevator cable makes several trips up and down the hoistway. As a result, compensating ropes "compensate" for the entire weight of hoisting ropes on the car or counterweight side. These ropes, which are connected to the sling that holds the car and the counterweight frame, are probably required in any elevator that travels more than 100 feet.

The most important aspect of any elevator rope is that it be in good working order at all times. This means inspecting frequently. When performing routine checks, the technician must inspect the ropes closely for proper tension, any wear patterns, the diameter of the rope, any rusting, pitting, or breaks in the strands, the sheaves, proper lubrication, and connections.

So, when you choose a traction elevator, you will pay significantly more in monthly maintenance fees. You will also need to monitor the frequency of visits and the length of time the mechanic spends in the machine room, overhead, and hoistway. You're paying through the nose, so make sure they're doing what they're supposed to be doing. If you have any questions, talk to an elevator consultant, work with the elevator inspector, ask lots of questions, and discuss your concerns. If all else fails, contact another independent elevator technician to inspect the situation and provide an opinion on current maintenance.